Regarding flexo printing, computer software has been taking up an increasingly significant role in deciding the quality and efficiency of flexo plate engraving. As printing technology has developed, the software used in flexo plate designing and production has also developed. Let’s read more about how modern computer software is modifying the engraving of flexo plates.

Historical Background

The traditional flexo plate engraving was a mechanical process that involved the use of hands and other tools and mechanical techniques. Operators used to cut and shape plates manually and this was very time-consuming and full of errors. Another advancement that was incorporated in the flexo plate making was the use of computer software which enhanced precision and automation in the process.

Software Combination

The Flexo plate production process is highly computerized at each stage of the process through modern computer software. It begins with the design phase where graphic designers create complex digital files with the help of complicated design instruments.

Design Software

Software that is used for creating high-resolution graphics such as Adobe Illustrator and Corel DRAW. These programs allow the designer to work with vector images which are very crucial in making sure that the final print is sharp.

Engraving Software

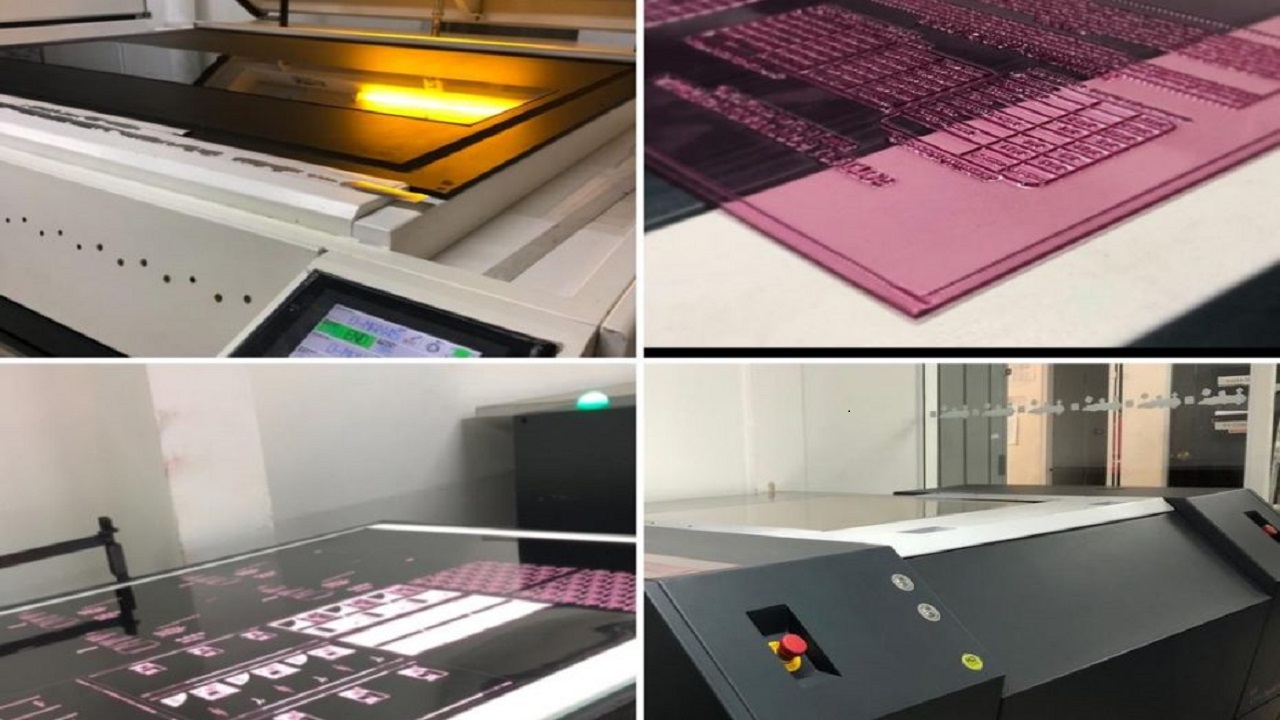

This software is used to accept the design files and organize them for the engraving to be done on them. It interprets the digital designs into instructions that the engraving machine requires whether it is a laser or an electronic engraving machine.

Automation and Efficiency

The benefit that is linked to the use of computer software in flexo plate engraving is automation. The engraving process which used to take a lot of time and required a lot of manual work can now be done automatically.

Precision and Accuracy

Computer software enables one to replicate all the aspects of the design on the plate right down to the finest features. This is very important in the printing process especially when it comes to quality printing where even the slightest differences can be a big deal.

Speed and Productivity

The software regulates the parameters of engraving and commands the machines, and therefore the rates of production have increased significantly. This makes it possible for printing businesses to be able to handle large orders and deliver within the shortest time possible.

Quality Control and Optimization

Modern software is also used in quality control and the improvement of the processes. Advanced systems offer feedback in real-time, and this helps the operators to make corrections as they continue with their work.

Real-Time Monitoring

One can automate the process of engraving and receive information about the work and its quality. This information is very useful in the process of analyzing the results and identifying where the issue is in case the results are not desirable.

Optimization

From the production data, it is possible to enhance the engraving process with the help of software. This ranges from the optimization of parameters to improving the quality of plates and reducing wastage since it is cost-effective.

Conclusion

In conclusion, the use of computer software in flexo plate engraving has been made more efficient, accurate, and less time-consuming as compared to the past when it was done manually, and that was associated with a lot of mistakes. Therefore, the flexo printing industry can achieve improved quality of prints and enhanced productivity using advanced design and engraving software that will form the foundation for the growth of the field.