Electric power steering (EPS) systems are now considered a standard feature in the rapidly growing automotive industry. Integral to the operation of these systems are EPS belts that are critical to smooth, efficient, and reliable steering. This article explains what an EPS Belt is, why that is critical in vehicles’ safety, and their benefits.

Steering Systems

Conventional hydraulic power steering systems use engine-driven pumps and fluid systems in their operation. These setups, though practical, were less effective and more likely to develop problems with maintenance. Electric power steering has made the mechanism of the vehicle more efficient and less energy-consuming. EPS systems an electrical motors that help in steering consume less energy and are more accurate than other types. The core of this innovation is the EPS belt through which power is transferred smoothly from the motor to the steering assembly.

The Functionality of EPS Belts

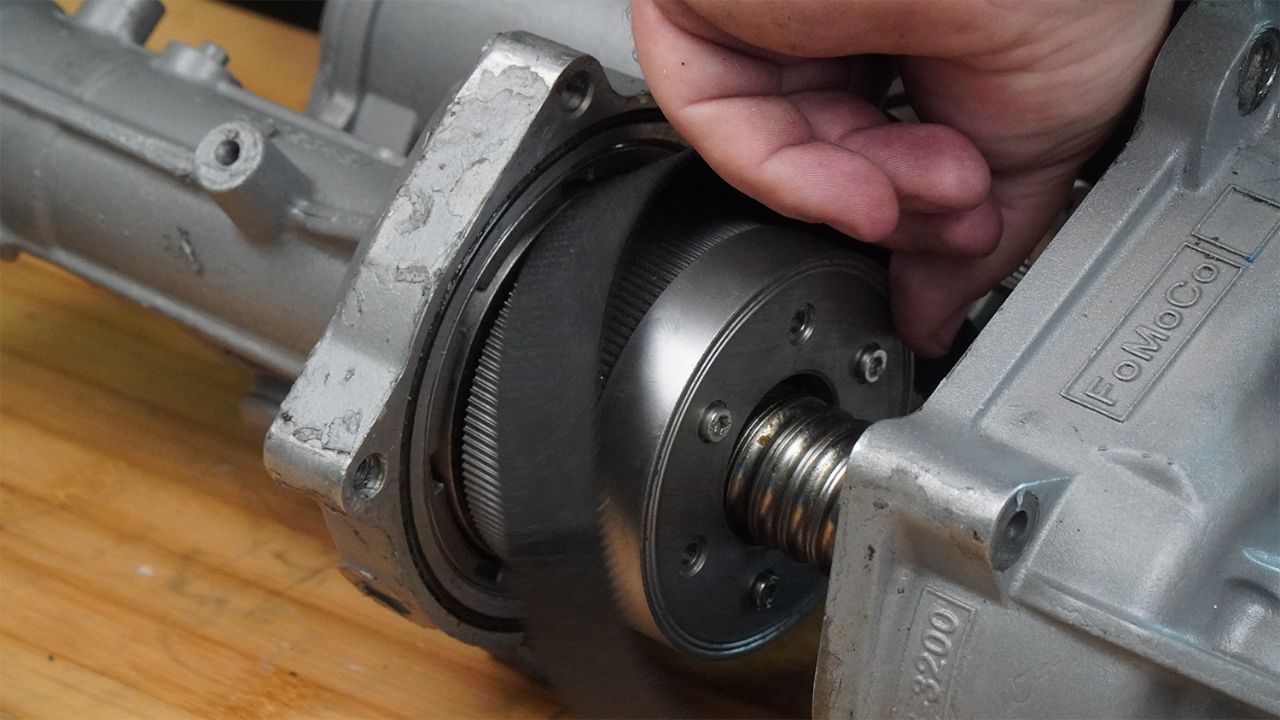

EPS belts are developed to transmit high torque and guarantee the accurate transmission of power in electric power steering systems. These belts link the electric motor to the steerage system, for a more sensitive and efficient feel of the car. EPS belts are designed in a way that they are made from high-strength rubber and synthetic materials to provide flexibility and durability and to withstand wear and tear. Apart from maintaining lower friction and vibration, EPS belts enhance a silent and smoother drive experience. Their light nature also improves vehicle efficiency which is in line with current trends of environmental consciousness and efficiency on fuel use.

Advantages of EPS Belts

Improved Efficiency:

Compared to conventional hydraulic systems, the EPS systems with belts help to minimize the parasitic load on the engine and, therefore, improve fuel consumption.

Enhanced Durability:

Indeed, EPS belts are specifically made out of materials that are suited for high temperatures and demanding conditions, so as to ensure that their performance does not degrade even when utilization is frequent, without much-required upkeep.

Precision Steering:

The qualified operation of EPS belts enables the drivers to get better control and rotation specifically during slow-speed operations such as parking.

Energy Savings:

EPS systems use power when required and this is very important in electric and hybrid vehicles because of energy saving.

Impact on Vehicle Safety

EPS belts are very important in maintaining the dependability of electric power steering systems which are very important in the safety of vehicles. A well-functioning EPS system helps in avoiding accidents by providing the right steering and minimizing fatigue. Also, today’s EPS systems can be connected with ADAS like lane-keeping assistance and parking aids, so high-quality and highly stable EPS belts are required.

Challenges and Maintenance

However, EPS belts come with some certain level of benefits but require appropriate maintenance to yield the right results. Backlash is another area of concern since everything like belt tension, alignment, and wear, therefore needs to be checked periodically to avoid system failures. These include self-tension mechanisms and better material types, but what has been found to maintain the belts, in the long run, is sometimes forgotten by the manufacturers.

Conclusion

The electric power steering (EPS) belt is one of the most overlooked components in today’s automobiles. In contributing to efficient power transfer, precise steering, and vehicle safety, EPS belts represent the future growth of automotive engineering. Comprehending these adaptations will be crucial when visualizing the future of vehicle driving experience as producers carry on with the progressive alteration of vehicles through electrification and prospects for automation, it is only clear that the EPS belt will remain an integral component in the equation.