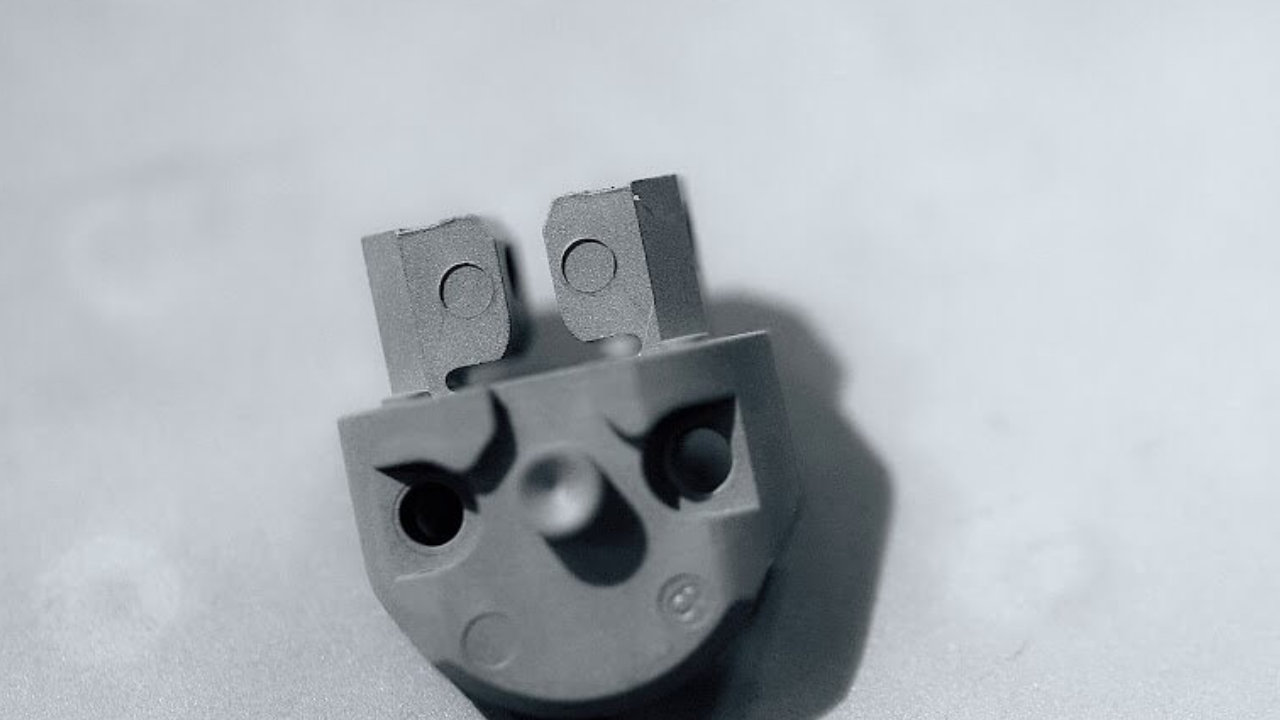

Although making plastic components is the primary use for injection molding, the technique is successful when producing complex metal parts in huge quantities. Plastic injection molding is quite similar to metal injection molding as a method of producing metal. Its feedstock, however, is a mixture of finely powdered metal and a binder, which is injected into a mold using conventional injection molding equipment instead of plastic pellets.

The feedstock shot typically weighs no more than 100 grams, restricting the process to smaller parts. The “green” sections need to go through more processing when the injected material has cooled. An extremely porous “brown” portion of metal is produced after removing the binder ingredient using heat or chemical treatment.

To boost the density and tensile strength of the brown components, they are sintered at a temperature around the melting point of the metal. After that, other post-processing procedures like plating or post-machining could be performed. To learn more about Metal injection molding can visit the 3ERP online store. They offer excessive, first-class manufacturing answers that can have your layout completed in a matter of hours.

What Type Of Equipment Is Used In The Metal Injection Molding Process?

In a unique method known as metal injection molding, finely powdered material is combined with a binder to form a feedstock. It is then injected to obtain a complicated formed shape in a far shorter amount of time than in a typical procedure. MIM technology often makes use of off-the-shelf equipment with specialized modifications. In order to tailor their equipment to our unique specifications, many of Indo-MIM’s US and European equipment suppliers have developed strategic relationships with the company.

The Process Of Metal Injection Molding In Steps

Utilizing this technology effectively mostly entails:

Feedstock Preparation

The preparation of the feedstock, which consists primarily of the mixture of raw materials required subsequently for metal injection molding, is the initial phase. The qualities of the finished metal injection molded goods are mostly determined by the attributes present in the metal powders produced by this technique.

In contrast, after the MIM injection molding is finished, the binder is utilized to inject the molding and is then removed from the finished goods. In a nutshell, the metal powder that is still present in the metal pieces is what is ultimately produced. This MIM feedstock’s granulation size is taken into account when creating it. You can buy the feedstock from reliable metal injection molding firms that produce this equipment to simplify the procedure and concentrate on quality.

MIM Injection Molding Process

The second stage of the metal injection molding process resembles the plastic injection molding process quite a bit. The MIM process can be used to create a range of geometrical metal pieces using the feedstock. After the procedure is finished, the machine forms green MIM parts similar to how it forms plastic parts.

Debinding

The debinding procedure is simpler to carry out because the pieces are green and in their early stages. Following the destruction of these binder components by an interconnected, non-geometric pore network, these MIM sections acquire a yellow color. The considerable binder substance is mostly removed during the debonding process, but some of it is still present in the pieces. The remaining binder substance holds the metal granules together. However, the remaining binder material begins to evaporate from the pores of the metal components during the first stage of sintering.

Sintering

The majority of the pore volume that the binder material occupies will be removed during this procedure. As a result, as soon as the sintering process is through, the yellow metal injection mold pieces will begin to shrink at a linear rate of 15%–20%.

The sintered parts are ultimately fully ready to be processed using traditional metalworking techniques comparable to those used on in order to achieve the desired level of final finishing for use and supply in various types of metal MIM parts.

Summary

A few thousand to several million components per year are commonly produced using MIM, which is ideally suited for medium to high manufacturing levels. Due to the economies of scale attained by the use of multi-cavity molds and the effective utilization of raw materials, the procedure is affordable for large volumes.